Magnetic Particle Inspection: Safeguarding Australian Manufacturing and Rail Industries

Detect Flaws Early, Prevent Failures

About Contact UsMagnetic Particle Inspection: Key Applications in Manufacturing and Rail Industries in Australia

Magnetic Particle Inspection (MPI) is a crucial non-destructive testing method widely used to find defects on or just below the surface of ferromagnetic materials. In Australia’s manufacturing and rail sectors, MPI plays a critical role in ensuring the safety, quality, and reliability of components foundational to everyday industry and public transport. This blog post explores vital MPI applications in these industries, highlighting specific use cases, defect detection, and consequences of skipping these inspections.

What is Magnetic Particle Inspection? An Overview for Australian Industries

MPI is a straightforward yet highly sensitive technique using magnetic fields and fine iron particles to reveal discontinuities like cracks and corrosion in steel, iron, and other ferromagnetic metals.

- A magnetic field is applied to the test piece.

- Iron particles, either dry powder or suspended in liquid, are applied.

- Particles gather at magnetic flux leakage points caused by defects.

- Visible indications form that inspectors assess under normal or ultraviolet light.

Due to its speed, cost-effectiveness, and accuracy detecting surface and near-surface flaws, MPI is the go-to method across heavy industries in Australia. It is especially valuable because it can be used on complex shapes and large structures either in factories or field locations.

Manufacturing Quality Control: Using Magnetic Particle Inspection to Ensure Product Integrity

Key MPI Use Cases in Australian Manufacturing

- Incoming Raw Materials Inspection: Detects cracks, laps, and inclusions in steel forgings, castings, and bars before production starts. This screening ensures that only defect-free materials proceed, saving costs from scrap and costly rework.

- In-Process Inspections: Carried out at forging, heat treatment, machining, and welding stages. MPI confirms no cracks or laps form during these stress-inducing manufacturing steps.

- Final Product Verification: Before dispatch, components such as crankshafts, gears, shafts, and welded assemblies are tested to guarantee zero surface or near-surface defects.

- Batch Sampling for Quality Assurance: MPI is used on sample parts from a lot to monitor production consistency and process stability.

- Regulatory and Standards Compliance: Australian manufacturers follow standards like AS 3862 or ISO 9712, incorporating MPI for certification and ensuring products meet safety and quality requirements.

Impact of Neglecting MPI in Manufacturing

- Undetected Defects Cause Early Failures: Small surface cracks or laps can grow into catastrophic faults under stress, leading to breakdowns or recalls.

- Higher Warranty and Repair Costs: Manufacturing faults that escape detection result in expensive returns, repairs, and loss of customer confidence across sectors like automotive, mining, or heavy machinery.

- Workplace Safety Risks: Components such as lifting gear or structural parts failing unexpectedly pose hazards for workers, potentially breaching Australian workplace health and safety laws.

- Regulatory Non-Compliance: Not conforming to Australian Standards and inspection norms risks legal penalties, product bans, and loss of certification.

- Manufacturing Process Inefficiency: Without MPI insights, tracing defects is harder, reducing improvement opportunities and causing ongoing productivity and quality issues.

MPI in Rail and Transportation: Safeguarding Australia's Critical Infrastructure

MPI Use Cases Specific to Rail and Transportation

- Rail Track Inspection: Detects fatigue cracks and stress corrosion cracks in rails, preventative to rail breaks that cause derailments and service disruptions.

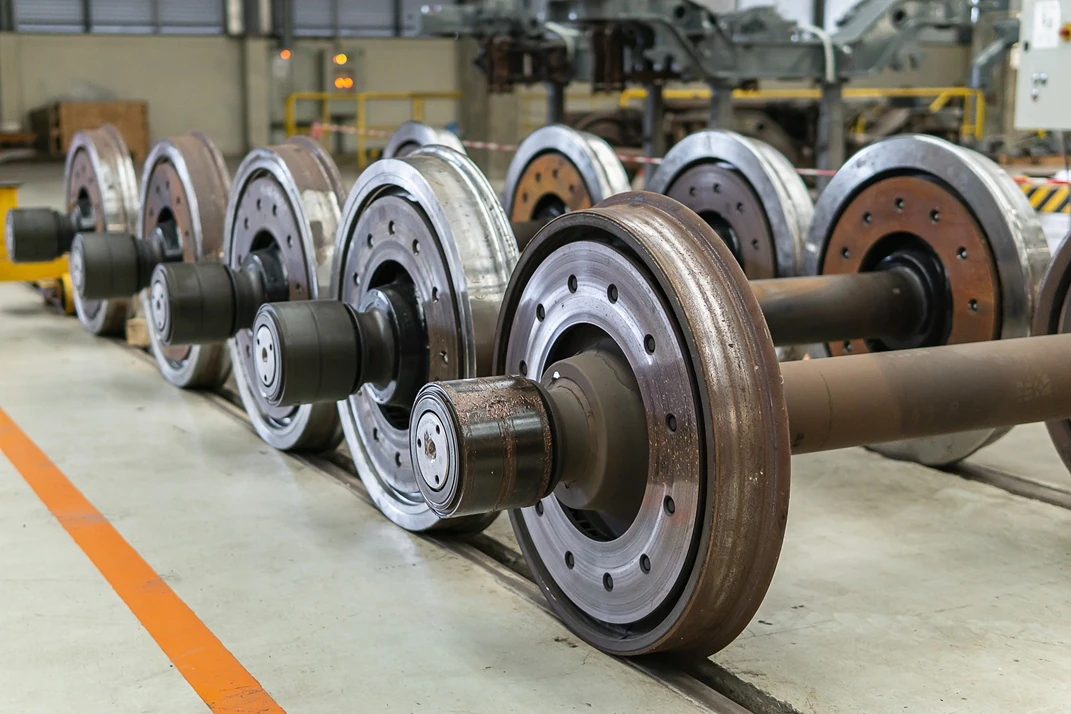

- Axle Integrity Checks: Axles hold trains and rotate under massive loads. MPI detects transverse and longitudinal cracks using equipment that magnetises axles internally or externally.

- Wheel and Tyre Testing: Inspects forged train wheels and steel tyre components for flaws that might cause fractures.

- Welded Assembly Inspection: Critical welds on bogies, frames, and suspension parts undergo MPI to catch cracks or porosity that could cause failure under dynamic loading.

- Spring and Suspension Components: Leaf springs and suspension elements are tested for fatigue cracks impacting ride safety and comfort.

- Automated Inspection Systems: Australian rail yards and maintenance depots often use motorised coil MPI systems to speed inspections while maintaining sensitivity.

Differences Between Rail Industry and Manufacturing MPI

| Aspect | Rail and Transportation MPI | Manufacturing Quality Control MPI |

|---|---|---|

| Purpose | Safety and operational integrity in service and maintenance | Defect detection during or post-production |

| Frequency | Scheduled maintenance and overhaul programmes | Batch sampling and final inspections before delivery |

| Components | Rails, axles, wheels, bogies, springs | Raw materials, forged parts, machined components |

| Inspection Environment | Workshops, rail yards, field service locations | Manufacturing plants, assembly lines |

| Techniques | Automated motorised coils, portable yokes, bench units | Portable devices, bench-mounted units |

| Cycle Time Consideration | Fast throughput for minimal service disruption | Balanced thoroughness and production speed |

Consequences of Skipping MPI in Rail and Transport in Australia

- Derailment and Safety Incidents: Cracked rails or wheels can cause train derailments risking passenger and workforce lives.

- Service Disruptions: Unplanned failures cause costly delays and repairs, affecting Australia's public transport and freight systems.

- Non-Compliance with Safety Regulations: Australian rail safety laws mandate routine inspections; neglecting MPI risks shutdowns and legal penalties.

- Reduced Asset Lifespan: Undetected cracks accelerate wear, increasing replacement costs.

Conclusion: MPI as the Backbone of Australian Industrial Safety and Quality

Magnetic Particle Inspection (MPI) is pivotal across Australian manufacturing and rail sectors, including key hubs like Newcastle and Sydney, preventing failures, ensuring regulatory compliance, and saving lives. In Newcastle, specialised Magnetic Particle Testing Newcastle services help manufacturers control product quality from raw materials to finished goods, reducing costly recalls and workplace hazards.

Similarly, Magnetic Particle Inspection Sydney supports rail and transport industries in safeguarding critical infrastructure vital to national safety and economic activity. By integrating highly sensitive MPI methods tailored to each industry's specific needs, Australian cities such as Sydney and Newcastle uphold world-class standards for reliability and safety.

Ongoing innovations in automated and field-appropriate MPI technologies will continue to strengthen this critical role across the country.

For detailed information about related inspection methods and standards, see our pages on Welding Inspection and Non-Destructive Testing.

Frequently Asked Questions (FAQ)

- What materials can Magnetic Particle Inspection be used on? +

- MPI is effective on ferromagnetic materials such as steel and iron. It cannot be used on non-ferromagnetic metals like aluminium or copper.

- How often should MPI be performed in manufacturing? +

- Frequency depends on standards and criticality of the components, but typically inspections occur during raw material arrival, in-process stages, and final product verification.

- Is MPI a destructive testing method? +

- No, Magnetic Particle Inspection is a non-destructive testing method that does not damage the parts being inspected.

- Can MPI detect internal defects? +

- MPI primarily detects surface and near-surface defects. It is not suitable for deep internal flaw detection.

- Are there any safety concerns when performing MPI? +

- Proper safety protocols must be followed, especially regarding the use of magnetic fields and UV light sources, to protect operators and surrounding equipment.

Comprehensive NDT Solutions: The APEC Inspect Advantage

APEC Inspect offers a complete range of NDT and inspection services, each complementing the others to provide comprehensive asset integrity solutions. Our Newcastle-based team brings decades of combined experience across all major industries in New South Wales and beyond.

Why Choose APEC Inspect?

- Comprehensive Expertise: From basic visual inspection to advanced PAUT, we offer the full spectrum of NDT services.

- Australian Standards: All our work complies with relevant Australian and international standards.

- Certified Personnel: Our team maintains current certification across all inspection methods.

- Modern Equipment: We continuously invest in the latest NDT technology.

- Customer Focus: We understand that each client's needs are unique and tailor our services accordingly.

Industry Coverage

We serve multiple sectors including:

- Mining and Resources

- Manufacturing

- Hydrogen Plants

- Power Generation

- Oil and Gas

- Marine

- Construction

- Infrastructure

Contact Us

For more information about any of our services or to discuss your specific inspection needs, contact our Newcastle office. Our technical team is ready to develop a comprehensive inspection program tailored to your requirements.

Recent Posts

APEC Inspection

The APEC Inspection Team are experienced in providing a wide range NATA Accredited third-party Inspection services. We have worked on national and international projects, from offshore oil and gas drilling rigs, to underground coal mines. We pride ourselves on providing quality pressure vessel inspections and non-destructive testing (NDT).

© apecinspect.com.au. All Rights Reserved. Designed by Peritus Digital